The Group of EMS manufacturers are one of the top manufacturer’s in the respective region since 1997. With the philosophy to provide our customers the Total Solution with a One Stop Facility for Contract Manufacturing and Assembly Services (EMS) facilities in China and U.S.A. and Associates Facilities in Malaysia.

The Group is committed to build the Resources, Technologies, Manufacturing Expertise and Business Structures to respond to our customers’ ever increasing needs. Our experienced and dedicated staff will attend quickly to all product requirements and specifications.

Process Capabilities

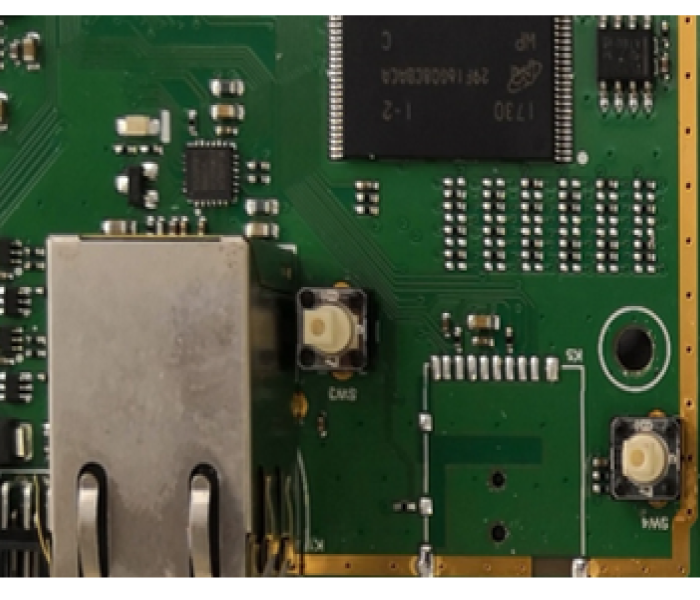

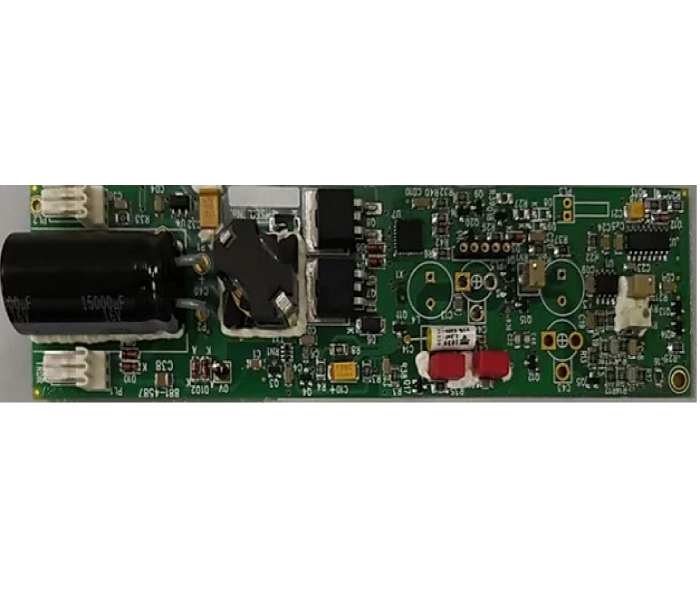

We offers comprehensive Electronic Manufacturing Services (EMS) that include Design, Prototypes, Board Level Assemblies, Sub-Assemblies, and Full Box Build Assemblies. Qualified for RF, Telecom, Medical and Military Products

Supply Chain

Within the Group, we have the manufacturing facilities that enhance position of our assemblies such as:-

MCT Global is the logical choice for final assembly of your product. Throughout your project build, you work with only one source eliminating problems that can occur when working with multiple sources. This streamlining of the production process reduces costs and enables us to provide our customers world class products of the highest quality and ready to be placed on store shelves.

Manufacturing Facilities

Product Presentation

Quality Certification